Development of a gas adsorption heat pump for the renovation of existing buildings

Funding code: 03ET1554 A/B/C/D/E

Funding period: 08/2018 until 02/2022

Project partner: Fraunhofer ISE, Fraunhofer IFAM, Fahrenheit GmbH, Herrmann GmbH + Co. KG, Haugg-Kühlerfabrik GmbH, KIT, DVGW-EBI

Objectives

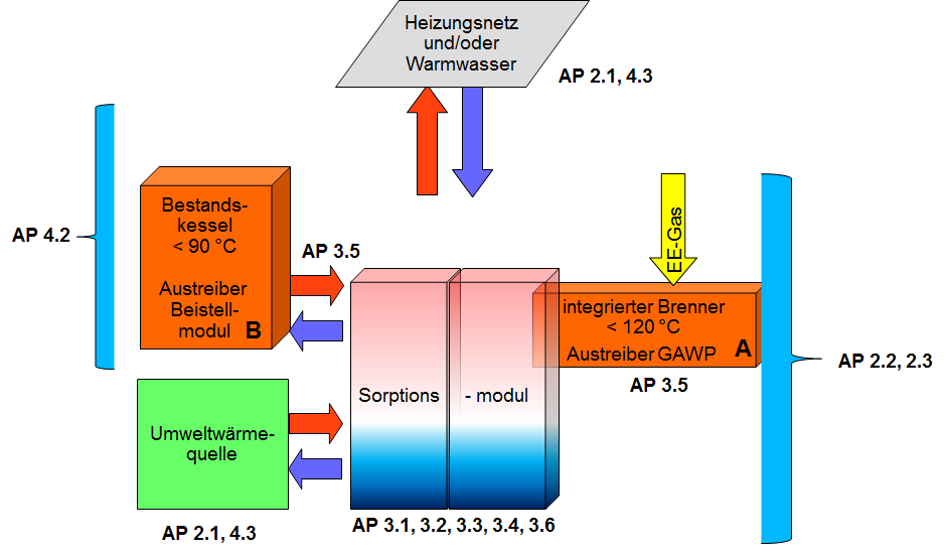

- Development of a gas heat pump (GHP) system for the renovation of MFH on the basis of a high efficient and powerful adsorption module

- Solution as add-on device for existing boiler or with an integrated burner

- Demonstration of the implementation and attainment of the annual primary energy ratio > 1.3 (> 1.4 for low temperature systems)

- Preparation of a system control for optimum combination of the heat pump module with the burner and the integration hot water

- More advanced burner including control also for operating with renewable gases

- Development work on high temperature adsorption module (drive >120°) for higher heat circuit temperatures or higher primary energy ratio

Technology

Fahrenheit GmbH develops high-performance fiber-composite adsorbers (ADOSO) and sorption module and produces operating models.

Haugg GmbH and Fraunhofer IFAM develop production technology for fiber-composite adsorber, evaporator and module (sintering and soldering in a CAB process)

Hermann Burners and DVGW-EBI develop burners and burner control (incl. gas flexibility).

Fraunhofer ISE works on system design, develops appliance and system control, carries out test bench measurements, coordinates demonstration

KIT works on modelling and simulation, especially for optimised processes/cycles in different operating situations and loading conditions, analyses components dimensioning and carries out variant analysis.

Work plan

Market requirements:

Demonstration of the basic framework conditions for the GWP development; determination of the components and setting up of a cost model

System development:

Process and hydraulic schemes, examination of different load situations via simulations, control and device development

Components development:

Efficient and cost-effective production technology adsorption module, adapated burner with fuel-flexible control

Assessment:

Experimental evaluation of the GWP as well as validation of the models; design of the demonstration systems

High temperature basic principles:

Work towards developing the future generation of gas heat pumps; examination of adapted sorption materials for exploiting the high temperatures of the gas burner and its production; new cycle concepts

Device measurement in field:

Measurement and operation optimisation of the developed GHP systems; development of the monitoring concept together with the A&D project